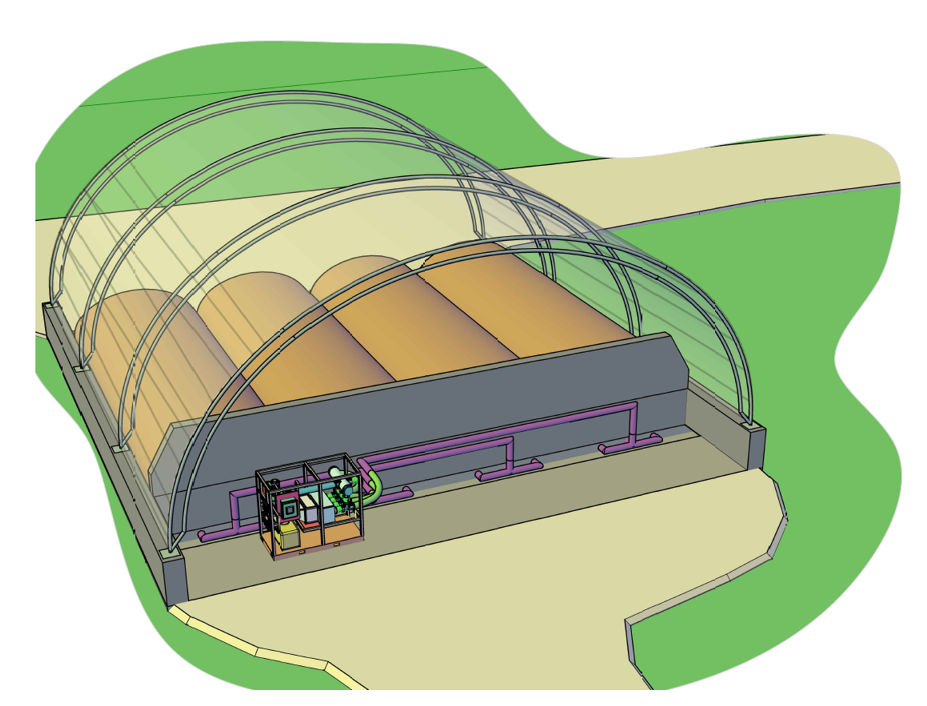

The AGT Compost Hot Skid 250-4R was built with the frugal dairy farmer in mind bringing all the core expertise and functionality of Agrilab Technologies Inc. (AGT) systems in a pared-down simple package. The equipment offers value, durability, and process control with labor and energy efficiency.

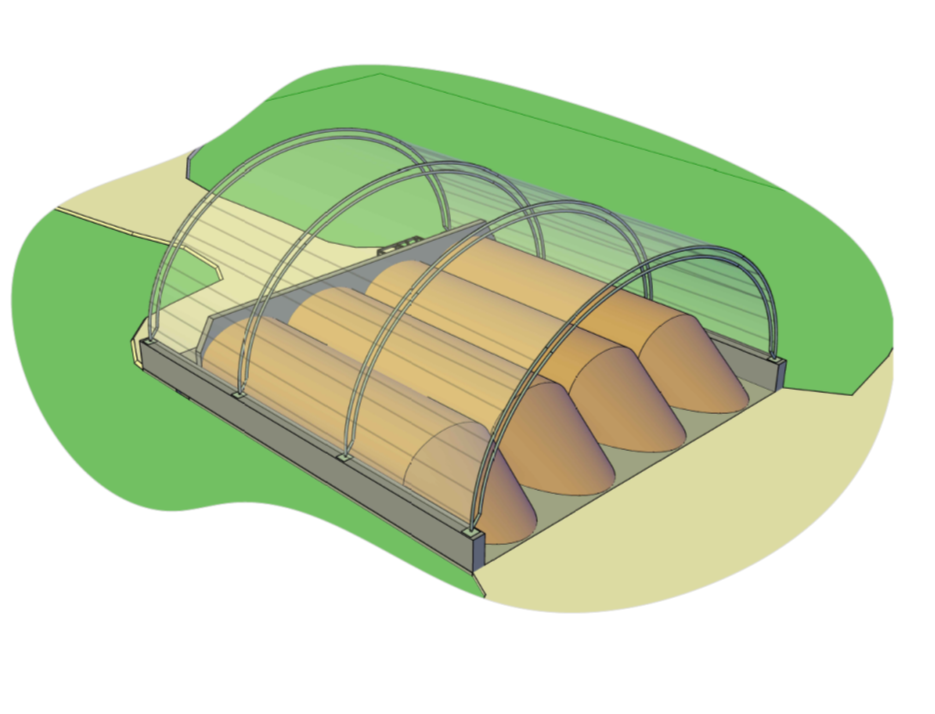

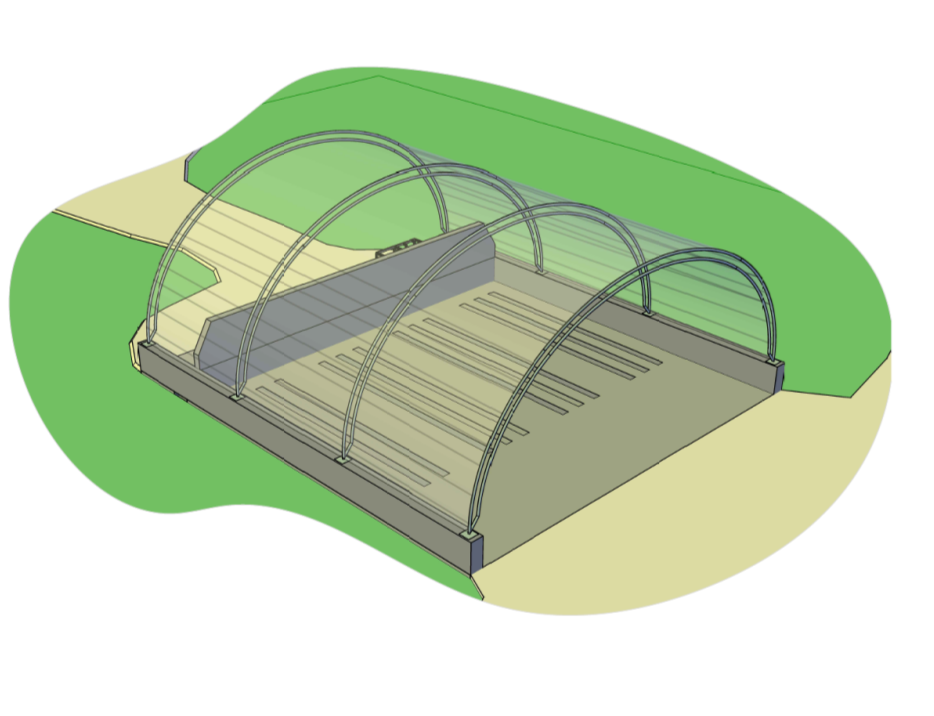

The AGT Compost Hot Skid 250-4R was built with the frugal dairy farmer in mind bringing all the core expertise and functionality of Agrilab Technologies Inc. (AGT) systems in a pared-down simple package. The system can be housed in an existing shed or barn and contains all the mechanical and control elements to run four compost batches while recovering heat. The variable speed blower and aeration cycles can be adjusted to run compost batches of 100 to 200 cubic yards (CY), or up to 250 CY with more easily aerated material. This translates to a processing capacity of 33 - 150 CY per week for standard material or up to 200 CY for easily aerated material. The recirculation(R) feature accelerates new batch activity by pushing warm oxygen vapor from adjacent active compost into the base of a fresh mixture. This reduces the time to achieve 131F+ temperatures and enables winter operations.

With a typical four week retention time, site operators running 200 CY batches can process over 10,000 CY of inputs per year. Farms and facilities larger than 10K/year of volume use multiple units or our larger CAHR models.

Four windrows in a negative aerated static pile (ASP) system provides plenty of vapor for heat recovery, and the Hot Skid’s aeration and

recirculation system optimizes compost temperatures, heat recovery, and throughput.

Catlin Farmstead is a family-run dairy farm in Winchendon, MA with an on-farm cheese plant, farm store, and commercial composting enterprise, Black Gold Compost. The owners came to Agrilab Technologies Inc. (AGT) looking to increase their compost output while reducing the hours of time it took to produce. The AGT team reviewed the farm's needs and recommended the AGT Compost Hot Skid 250-4R and other updates to meet their process and product goals.

Catlin Farmstead had an existing aerated bin system that was under performing and producing wet compost that was very difficult to screen. The AGT installation included upgrades to the aeration piping, and connection of a Hot Skid 250 to four aerated bays, 180 cubic yard (CY) capacity each. The recovered heat is used with positive aeration to dry the curing compost product prior to screening. Their typical operation is mixing and loading 180 CY batches that have a four week aeration retention time.

Since installing the system in 2019 the farm has seen a dramatic increase in compost ready for sale while enjoying a reduction in unit processing costs leading to a much more profitable composting operation. Total compost sales revenues have increased every year since implementation due to more inventory available during key spring sales seasons, and local and regional demand and price increases.

The benefits that Jake, Allie, Mike and Leah at Catlin Farmstead have experienced are a prime example of the impact an AGT CAHR system and our services can have on a business.

Interested in learning more about the Hot Skid 250?