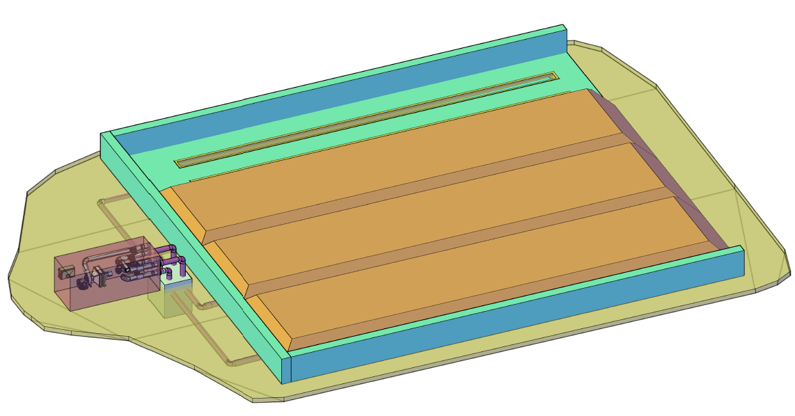

The Hot Box 1000 is an industrial compost aeration system with heat recovery and material drying capabilities, bringing all the core expertise and functionality of Agrilab Technologies Inc. (AGT) systems in a more powerful package.

The Hot Box 1000 is a scaled up, industrial compost aeration system with heat recovery and material drying capabilities. Like our smaller systems, the Hot Box 1000 contains all the electronics, sensors and moving parts to efficiently produce high-quality compost with minimal material handling, remotely accessible controls, and data tracking. The 1000 series is available with custom features, recognizing that at this industrial scale it is cost-effective to adapt to a site’s specific needs. Using powerful industrial components leverages the economy of scale for larger operations, with less maintenance per unit of compost.

The blower and pipe sizes can be adjusted to match batch volumes from 500 to 1000 cubic yards each, with four-zone and six-zone options. This means one Hot Box 1000 can be configured to aerate 2000 to 6000 cubic yards of active compost, and of course multiple units can be combined.

The compost heat available at this scale can create significant savings if connected to large users of heat such as greenhouses, shop buildings or process water systems. Heat exchangers are optional and can be sized to match the site needs, and may be added later if new heat uses are built.

Implementation Process

- Hot Box(es) built to order

- The site is graded, utilities (electric, hot water, data) and drainage pipes installed

- Sump tank is placed, HDPE pipes and aeration channels installed

- Push walls are built and concrete working pad(s) cast in place

- Hot Box is set in place and connected to aeration pipes, biofilter and utilities

- Electrical and data are connected, system is tested in place with empty pad

- Hot water system is connected

The Oslo Horse Show runs a well-apportioned composting operation near the Oslo Airport utilizing covered concrete bins. The bins, measuring 10m wide by 23m long, handle approximately 830 cubic yards (635 m³) per batch. The facility is very interested in capturing and selling the heat to a neighboring greenhouse business.

AGT completed a feasibility study and found that, using one four-zone Hot Box 1000, the business could double compost production on the same footprint, which showed a three and a half year payback on compost production alone. An additional $50,000/yr revenue was modeled by matching compost heat production with the greenhouse heating requirements.

Interested in learning more about the Hot Box 1000?